Cold Storage Company

Cold Storage Company

Room Cooling System for Warehouses and Cold Storage Units

How Cold Storage Projects Improves Food Storage and Distribution

Commercial Blast Freezer Buying Guide: How to Select the Best Model for Your Business

Energy-Efficient Cold Storage: The Future of Sustainable Refrigeration

ROI Calculation for Cold Storage Warehouse Investment: A Complete Guide

Welcome to the world of gas control systems in modern ripening chambers. Modern ripening chamber gas control systems: welcome!

Herein, we detail the complexity of such systems, their role in the banana ripening process, key components, and their impact on efficiency and profitability.

From Ethylene management to advanced sensors, we'll see how this system guarantees the best fruit quality special focus on the banana ripening chamber profit. Let's do controlled ripening now!

Ripening chambers are special environments designed to accelerate or control the ripening of fruits like bananas, mangoes and avocados.

The heart of every ripening chamber is the gas control equipment that controls the atmosphere to simulate natural conditions of ripening. With bananas, this matters because consumers want just the right texture, colour and flavour.

It begins with bananas picked green and firm enough to be transported. In the banana ripening chamber, gas control systems add a plant hormone called ethylene to initiate ripening.

These systems also regulate CO2, O2, temperature & humidity. Preserving precise conditions reduces waste and increases banana ripening room profit.

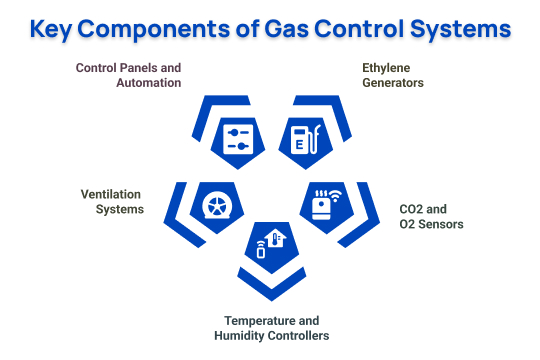

Modern ripening chamber gas control systems combine advanced technology with practical engineering. The major components are listed below.

These parts make up a controlled environment. At the center of the cold chain is the banana ripping chamber.

The banana ripening process in a ripening chamber follows a structured timeline to get optimal results. Here’s how it goes

This process ensures bananas reach markets in the best condition, directly impacting banana ripening chamber profit by reducing waste.

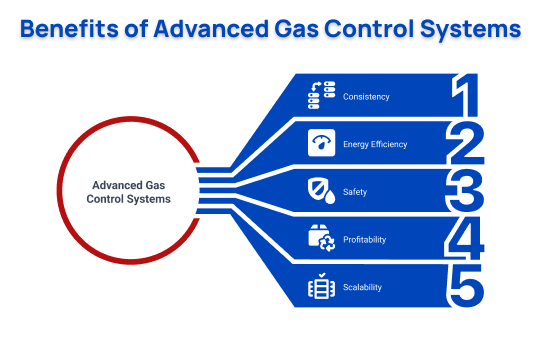

Modern gas control systems offer many benefits that boost ripening chambers:

These benefits make gas control systems essential for modern cold chain operations, especially in banana cold storage and ripening.

Despite the advantages, some problems with gas control systems should be managed.

With these challenges managed, however, businesses can maximise their ripening chambers' value and remain competitive.

New developments for gas control systems in ripening chambers are exciting. NDIR-based sensors, Iot-enabled controllers and sustainable practices follow along with global environmental goals, enabling remote monitoring and real-time adjustments in gas detection accuracy.

This translates to faster ripening cycle times, lower cost and higher profits for banana ripening chambers.

With technology, we will have more control over ripening and quality fruit for consumers.

The gas control systems are the heart of modern ripening chambers and allow precise ethylene, CO2, oxygen, temperature and humidity management.

Such systems automate the banana ripening process, with standardised quality, less waste production as a pulling factor for the banana ripening chamber's profit.

They marry up advanced sensors and automation with ventilation to turn banana cold storage and ripening into a science of dependability.

At Blue Ice India, we proudly offer you the best-in-class tailor-made ripening chambers.

We offer proven solutions to help businesses achieve better fruit quality and profit.

Want to optimise ripening operations? Contact Blue Ice India today for our cold chain solutions!

Queries

Gas control systems regulate ethylene, CO2, O2, temperature, and humidity to simulate natural ripening conditions, ensuring consistent banana quality.

By minimising spoilage, enhancing fruit quality, and reducing energy costs through automation, these systems increase the efficiency and profit of ripening chambers.

Yes, regular calibration and maintenance of sensors and dispensers are essential for optimal performance and accurate gas control.