Cold Storage Company

Cold Storage Company

Room Cooling System for Warehouses and Cold Storage Units

How Cold Storage Projects Improves Food Storage and Distribution

Commercial Blast Freezer Buying Guide: How to Select the Best Model for Your Business

Energy-Efficient Cold Storage: The Future of Sustainable Refrigeration

ROI Calculation for Cold Storage Warehouse Investment: A Complete Guide

Potatoes need careful handling after harvest to prevent spoilage and maintain quality for months ahead.

We are a trusted cold storage manufacturer and this guide describes cold storage and how to store potatoes in cold storage from preparation to monitoring.

Modern cold storage units extend shelf life, reduce losses and help India with its huge potato production.

We cover temperature controls & humidity management, cold storage facility types and cold storage project costs, including 2025 developments such as solar-powered options and energy-efficient designs.

Solutions from Blue Ice India help farmers and processors reduce waste and ensure year-round availability.

Farmers harvest potatoes during the short seasons but demand remains all year round. This demand is achieved with the help of cold storage facilities.

Cold storage involves refrigerating to create stable conditions that slow natural decay of produce such as potatoes.

These setups prevent sprouting, rot and weight loss in India where potatoes account for almost all agriculture.

Traditional methods used simple sheds, but modern cold storage uses sophisticated tech. Think insulated panels and CO2 scrubbers as well as humidity controls.

Blue Ice India for example builds these with high-density PUF panels that trap cold air well. Upgrading to these systems is essential as of 2025 with post harvest losses at 16% ICAR reported.

They preserve quality and meet government targets of cutting losses to 10% by 2050.

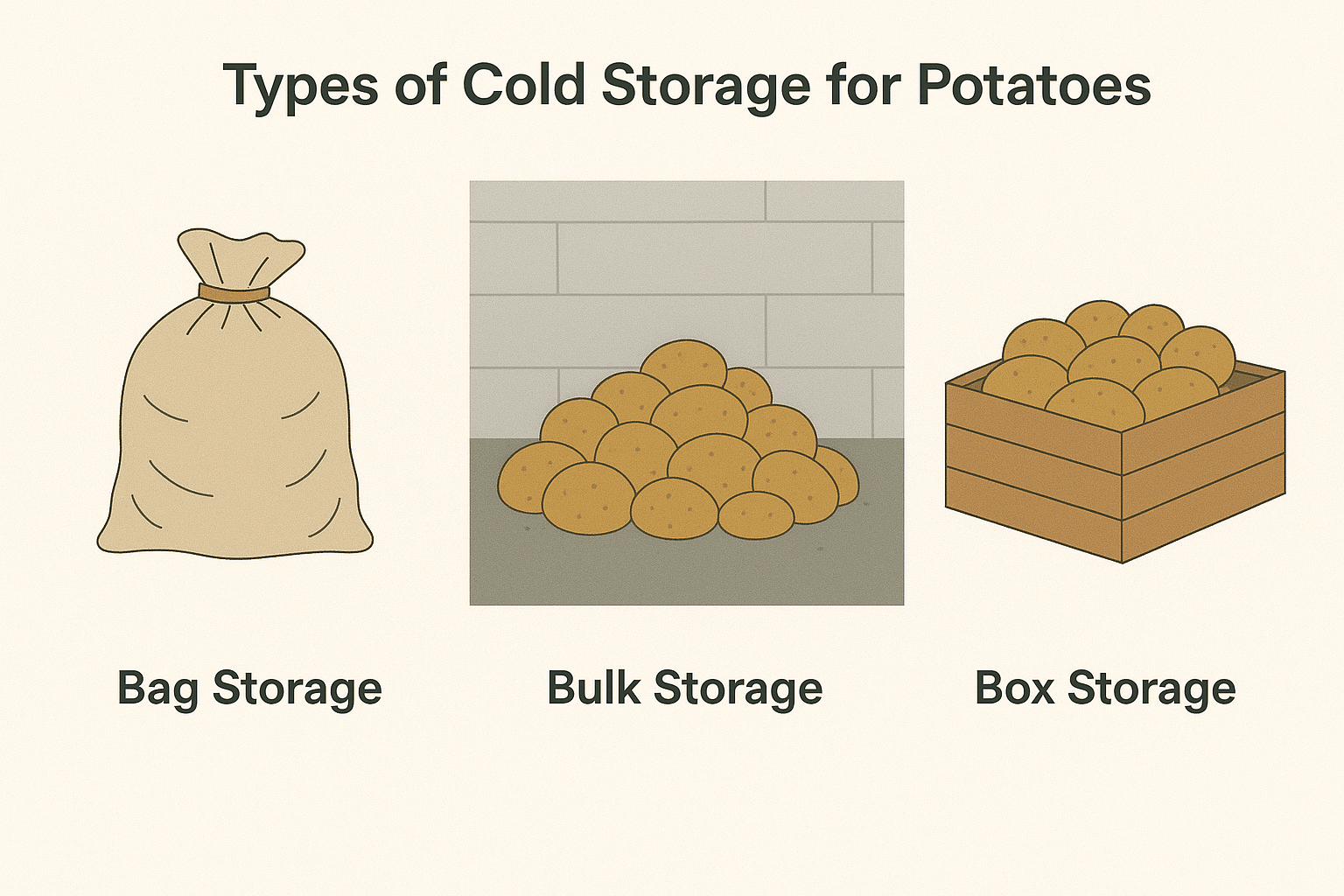

Potatoes require particular attention. High humidity causes mold, dry air causes shrinkage. Cold storage units even balance this out, often with ventilation systems moving fresh air. In Gujarat where bag storage is the most common because of lower cost, bulk and box models cold storage facilities offer longer preservation potential.

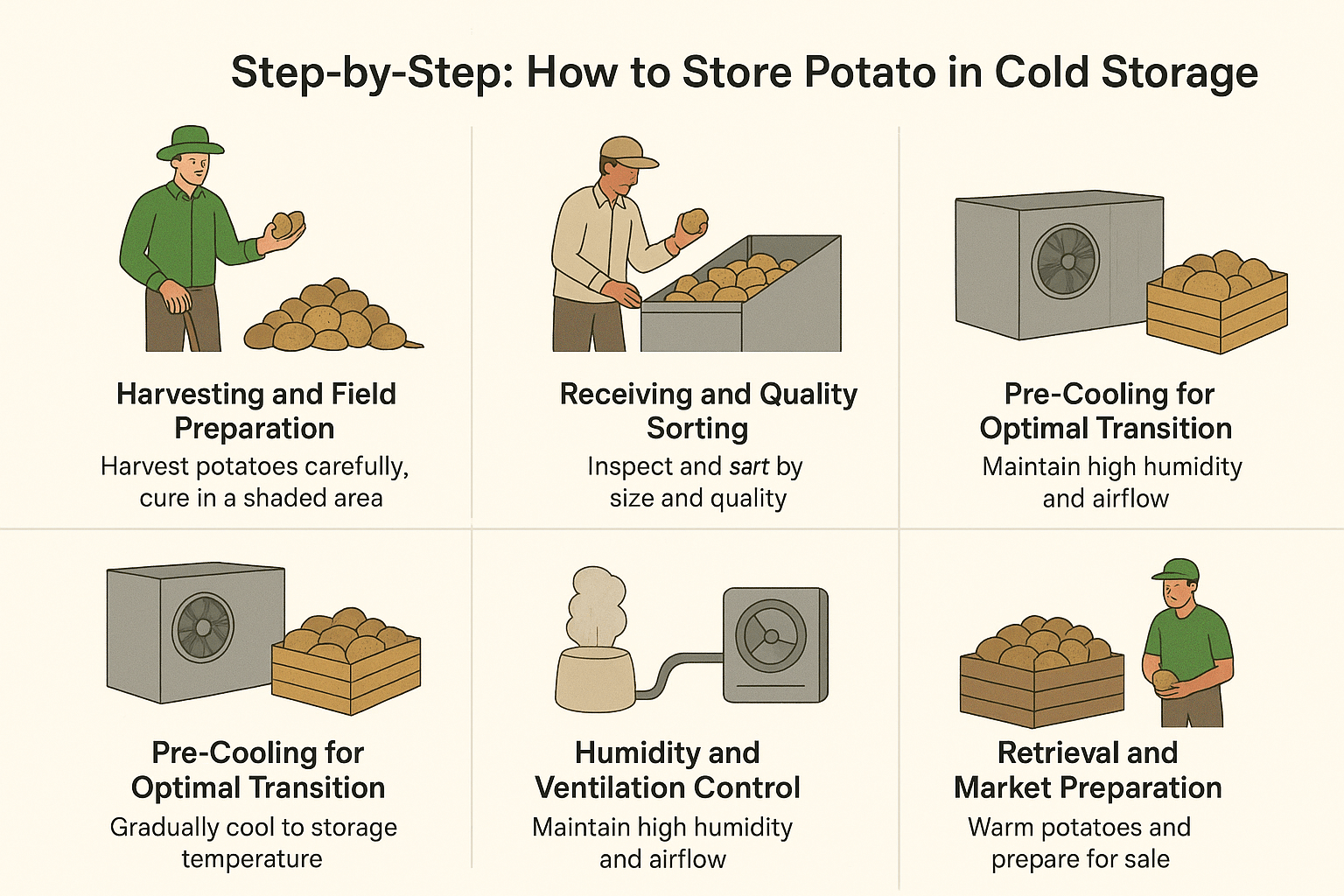

Start with careful harvesting to minimize damage to potatoes, as bruises or cuts can lead to rot during storage. Use gentle equipment or manual methods to pick up tubers from the soil with skins still attached.

Post harvest, cure potatoes in a shaded, well-ventilated area for healing of minor cuts and thickening of skins for durability.

Place them in breathable jumbo bags commonly available to prevent dirt and moisture buildup.

Covered vehicles transport promptly to a cold storage unit to prevent potato from heat and sunlight from causing early sprouting or quality degradation.

At the potato cold storage warehouse, transfer potatoes to a receiving bay, often with a hopper for easier handling. Inspect each batch for damaged, diseased or greening tubers that may spoil whole lots.

Sort potatoes by size and kind , seed, table or processing varieties because each needs different conditions of storage.

In modern cold storage facilities automated sorting lines with conveyor belts and optical sensors reduce manual handling and maintain quality for processors producing fries or chips.

Bring potatoes slowly into the cold storage unit to avoid shocking them with sudden temperature drops that may cause internal stress or condensation.

Use precooling chambers or other areas of the cold storage facility to circulate cool air from fans and refrigeration coils. Temperature adjustments depend on potato type: cooler for seed potatoes to maintain viability; slightly warmer for table, processing varieties to preserve flavor and texture.

Using this controlled cooling phase supported by systems like those from Blue Ice India, potatoes acclimate without compromising starch content or market quality.

Potatoes need high humidity to avoid dehydration, which causes weight loss and shriving. In a cold storage warehouse, mist the area to prevent mold growth with humidifiers or wet-floor techniques.

Ventilation is also important for carbon dioxide and ethylene gases that potatoes naturally give off and which may accelerate sprouting.

Install automated dampers, exhaust fans or CO2 scrubbers to cycle fresh air and harmful gases in the facility.

Advanced setups include IoT sensors for air quality monitoring - without manual intervention.

Place potatoes in the cold storage unit in breathable jute bags, bulk piles or ventilated crates, depending on how they were stored.

Bag storage, which is common in India, is suitable for short-term storage whereas bulk systems having underfloor ventilation/crates are suitable for longer preservation - suitable for processors. Position stacks so air can circulate around and prevent hot spots. Observe for signs of sprouting, softening or fungal growth and adjust temperature or humidity if problems occur.

Modern cold stores use microprocessor based controllers to maintain precise conditions and alerts for environmental changes so potatoes can remain viable for long periods.

When retrieving potatoes from the cold storage warehouse, slowly warm to ambient temperature to prevent condensation that causes sogginess or bacterial growth. Climate-controlled staging areas ease this transition while tubers remain dry and firm.

Verify the quality of the batch during removal by throwing away any compromised potatoes. Avoid bruising by handling them gently - especially table varieties for markets or processing plants.

This careful retrieval process ensures potatoes leave the cold storage facility in good condition to be sold or used in products like snacks or frozen goods.

We've covered the essentials of potato cold storage, from defining what is cold storage to the detailed steps of how to store potato in cold storage.

We at Blue Ice India build reliable cold storage projects for potatoes and other produce. Our PUF panels & refrigeration systems provide precise control at competitive cold storage prices. Call today to discuss your needs. Let’s create a solution that keeps your harvest fresh & profitable!

Queries

Potato cold storage is a facility designed to maintain specific temperature and humidity levels to slow decay, prevent sprouting, and preserve nutritional value. It is essential in India to reduce post-harvest losses, ensure year-round availability, and support farmers, processors, and consumers.

Seed potatoes: 2–4°C to maintain viability.

Processing potatoes (for chips/fries): 8–10°C to avoid sugar buildup. Maintaining humidity at 85–95% and proper ventilation is equally important.

Bag Storage: Economical, suitable for 6–8 months, but higher handling losses.

Bulk Storage: Automated, lasts 10–11 months, efficient for processors.

Box Storage: Long-lasting (10–15 years), ideal for size-specific processing, though costlier.