Cold Storage Company

Cold Storage Company

Room Cooling System for Warehouses and Cold Storage Units

How Cold Storage Projects Improves Food Storage and Distribution

Commercial Blast Freezer Buying Guide: How to Select the Best Model for Your Business

Energy-Efficient Cold Storage: The Future of Sustainable Refrigeration

ROI Calculation for Cold Storage Warehouse Investment: A Complete Guide

Find out why food, pharmaceuticals and logistics companies need a modular cold room.

Here is an article that describes how cold room solutions from cold room manufacturers like Blue Ice India improve efficiency, scalability and cost savings.

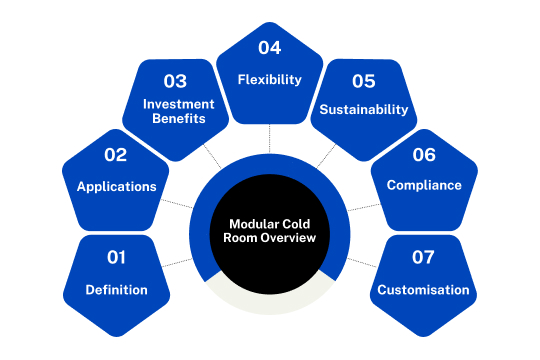

Learn how cold chain management utilises modular cold rooms, from defining what one is to its applications & investment value.

A modular cold room is a prefabricated, customizable storage unit designed to maintain precise temperature and humidity levels for perishable or sensitive goods.

In contrast to regular cold storage rooms (CRS), they are constructed using pre-engineered panels, usually of high-density polyurethane (PUF) foam, offering high thermal insulation.

These rooms are built by Blue Ice India using cyclopentane PUF panels for energy efficiency and Class O fire ratings for safety.

The modular design makes these cold rooms easy to assemble, disassemble and reconfigure, permitting adaptation to multiple business needs.

They are fitted with sophisticated refrigeration systems with microprocessor-based controllers and pressure safety switches to maintain product condition for seafood, pharmaceuticals, and fresh produce, among others.

Their versatility means they suit the hub-and-spoke model, with a central hub cold room served by smaller spoke units for distribution.

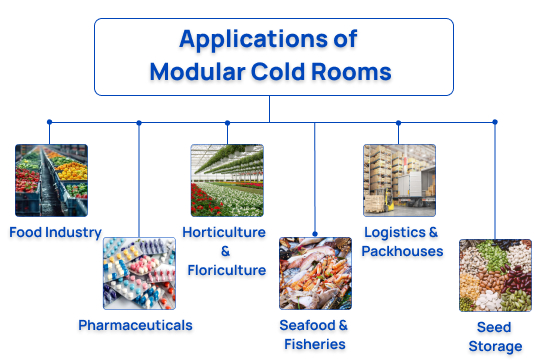

Modular cold rooms cater to various industries with temperature-sensitive storage. Their adaptability and relative precision make them a necessary component in the hub and spoke model, in which local spoke units support bigger hub facilities. Here are the key applications:

Blue Ice India offers modular cold rooms for these sectors with custom designs to suit storage requirements at precise temperature and humidity.

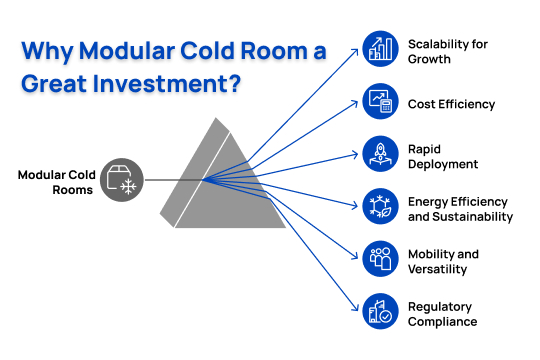

Investing in a modular cold room offers significant advantages, particularly within the hub-and-spoke model, making it a strategic choice for businesses aiming to optimise their cold chain. Here’s why:

Scalability for Growth: Modular cold rooms enable businesses to expand or change storage capacity as required.

Additional panels may be added to increase size, or units may be reconfigured for other purposes.

A logistics company, for example, could start with a small cold storage room at a spoke location and grow as demand grows, by hub-and-spoke efficiency.

Cost Efficiency: Modular units have lower initial investment than standard cold storage rooms because of prefabricated parts and a shorter construction time. Industry data show savings of up to 30% off initial investment.

Also, due to advanced insulation, energy consumption is reduced, and this reduces the long-term operational cost by up to 40% in some cases (for low RH applications such as chocolate storage) as compared to conventional insulation when using Blue Ice India PUF panels.

Rapid Deployment: Time-sensitive industries can install modular cold rooms in days. This minimises downtime so businesses like pharmaceutical distributors can keep operations running.

Blue Ice India's pre-engineered designs enable rapid assembly and are suitable for hub and spoke operations.

Energy Efficiency and Sustainability: Modular cold rooms become more efficient with rising energy costs and use high-quality insulation and green materials.

In Blue Ice India units, cyclopentane PUF panels are used to improve thermal retention and reduce energy loss.

This reduces utility bills and supports sustainable goals, and will attract environmentally conscious businesses.

Mobility and Versatility: The Ability to disassemble and move modular cold rooms adds long-term value. Seasonal businesses like horticulture farms can move units to new locations relatively inexpensively.

This enables mobility within a hub and a spoke model, where spoke cold rooms are redeployed as logistics needs change.

Regulatory Compliance: Cold rooms manufactured by Blue Ice India are built to industry standards and have control valves and temperature controllers for precise conditions.

This compliance is critical in industries such as pharmaceuticals, where product loss or regulatory penalties may result from improper storage.

At Blue Ice India, we've seen it ourselves how modular cold rooms improve business in terms of scalability, cost efficiency, rapid deployment, energy savings, mobility and compliance.

Such benefits, leveraged over the hub-and-spoke model, render them an important asset for the food, pharmaceuticals and logistics industries.

With our cold storage rooms, we guarantee product quality & we facilitate business in competitive markets.

Need help with your cold chain? As a leading cold room manufacturer, we at Blue Ice India provide customized modular cold room solutions.

Visit https: Find out more about our cold storage rooms by talking to one of our experts.

Queries

A modular cold room is a prefabricated, insulated storage unit designed to maintain specific temperature and humidity levels for perishable or sensitive goods. Unlike traditional cold storage, they are made with pre-engineered panels (like PUF) for better insulation and flexibility.

Absolutely. Blue Ice India's modular cold rooms use high-performance cyclopentane PUF insulation, which helps reduce energy consumption by up to 40%, significantly lowering operational costs.

Yes. Blue Ice India uses environmentally responsible materials, including cyclopentane PUF insulation, to ensure high energy retention and reduced environmental impact.